Source: Caterpillar

This article originally appeared on EquipmentWorld.com – a leading media site serving up the latest news in construction, heavy equipment, pickups and everything else that helps you get the hard work done.

It is re-posted with permission

Caterpillar has retooled its line of tilrotators for crawler excavators to deliver faster installation times, more hydraulic power and less downtime.

Multifunction capability on the TRS12, TRS17, TRS20 and TRS26 allows the attachment to simultaneously rotate 360 degrees and tilt up to 40 degrees to the left and right. Operators can efficiently perform a range of tasks – digging, grading and compacting – with more precision without repositioning the excavator, Cat says.

The new models are fully integrated with Cat excavators. When connected, the tiltrotator automatically shows up on the in-cab monitor and is controlled by the joystick.

“Our tiltrotators can be used with a wide range of attachments like buckets, grapples, compactors and more, allowing for higher machine utilization and improved productivity,” said Scott Rosengaard, Caterpillar senior product consultant. “Plus, the new standard tilt sensor delivers precise tilt and rotation angles to the grading system.”

High-flow system

The new tiltrotators feature a standard high-flow swivel, providing up to 52 gallons per minute at 3,626 psi for use with high-flow work tools. A second hydraulic line on next-generation Cat excavators boosts the hydraulic flow and pressure to 66 gpm at 5,076 psi.

New pressure compensated hydraulic valves manufactured with spools provide better control of the hydraulic flow than previous designs. This allows the tiltrotator to maintain stable rotation speed regardless of tilt speed, according to Cat.

Hydraulic attachments can be changed quickly thanks to a standard quick-connect interface. When equipped with the full hydraulic coupler, operators can now change tools without leaving the cab. Cat’s SecureLock sensor technology inside the locking cylinder verifies that the tool is correctly connected and locked to reduce the risk of swinging or dropping tools.

Easy maintenance

Cat TRS tiltrotator models feature a single grease point connection with the excavator’s auto-grease system, which automatically distributes the correct amount of grease to the appropriate points on the machine and attachment, the company says.

Double-acting tilt cylinders fitted with a load holding valve ensure the load is securely in position, even if the hydraulic system loses pressure. The worm gearbox is filled with oil for optimal lubrication and maximum heat distribution, according to Cat.

A plastic cover with built-in electrical harness provides easy connection to the hydraulic valves and simplifies servicing. A new frame design reduces dirt exposure for the grading sensor. It is also protected by a metal cover.

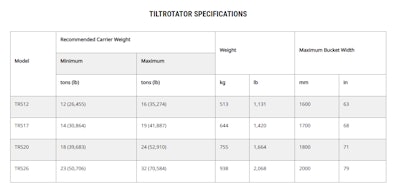

See below for Caterpillar’s recommended tiltrotator and excavator pairings:

Source: Caterpillar